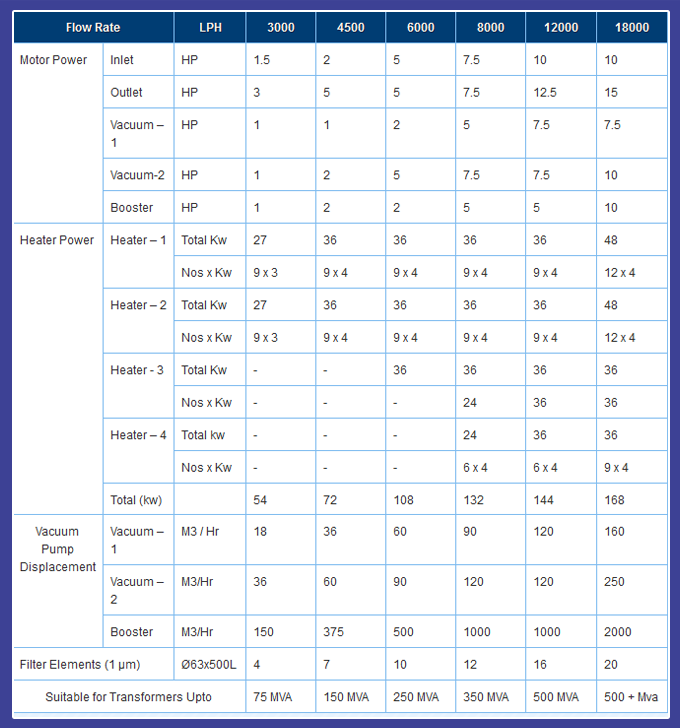

Two Stage Transformer Oil Filtration Plant

Two Stage Transformer Oil Filtration Plant, offered by us, is suitable for degassing, dehydration and filtration of transformer oil under vacuum and achieve oil test results as per I.S standards. It basically works on heating, filtration and vacuum treatment. Our Transformer Oil Filtration Plant has flow rates ranging from 300 LPH to 12000 LPH. We manufacture different models of Transformer Oil Filtration Plant as per the requirements specified by the buyers. We offer Transformer Oil Filtration Plant for on-site filtration, castor mounted for factory and site filtration and stationery for filtration of collected oil. Optional items such as ionic reaction column (for acidity correction), Spirafuge for coarse separation, transformer evacuation system can also be offered with the product.

Our 2-stage degassing plant has following components :« Prefilter : Oil comes through Transformer/Tank via inlet valve to Pre-filter. It has powerful magnet located inside

it. So, it adsorbs all magnetic impurities as well as provides protection to inlet pump which is positive

displacement type gear pump.

« Heater Tank : Inlet pump delivers the oil straight towards the heater. Heater tank is designed for heating of oil

through indirect type of heating. Heaters are suitably grouped to achieve power economy when oil quantity is

less.

« Ionic Reaction Column : This part of machine is used to reduce the acidity of oil. We use activated alumina for

the adsorption of acid particles when oil is passed over it.

« Filter Chamber : It has two layers of filters; one is 100 micron rating filter mesh & others are 1 micron rating

filter cartridges distributed evenly all over the area. 100 micron mesh is used for increasing the life of filter

cartridges as cartridges are to be replaced when choked. It reduces running cost of machine.

« Degassing Chamber : The function of this part is to remove moisture & entrapped gases in the oil. In these

type of machines, degassing chamber is divided in 2 stages by siphon. in The first stage connected to vacuum

pump, is used for removal of free moisture present in the oil. Second stage degassing chamber is connected

to the Booster pump which in turn is connected to high capacity vacuum pump. In this stage, entrapped

moisture & gases are removed. In degassing chamber, arrangements are made in such a way that thin film of

oil is exposed to vacuum for maximum period of time with help of shower arrangements, knitmesh packings,

etc.

« Outlet Pump : This pump is glandless centrifugal type. This pump takes of De-acidified, filtered & dehydrated oil

back to the transformer/ tank.

« Safety Interlocks :

• If your inlet pump is not turned on, heaters will not get turned on.

• If by some means, level of oil in degassing chamber rises & in turn rises float, inlet pump is turned off & in turn

are the heaters.

« Value-added services :

• If main supply is connected in reverse rotation, indicator will be glown on panel & no

motor will start.

• Solenoid valves are provided in vacuum lines so as to avoid oil rise into trap when suddenly vacuum pump is

stopped & airing is not done.

• By-pass connection is given in the machine so as to change the positions of hoses, without shutting down the

machine.

Technical Specifications Working Vacuum : <1 Torr ; Ulimate Vacuum : 0.005 torr